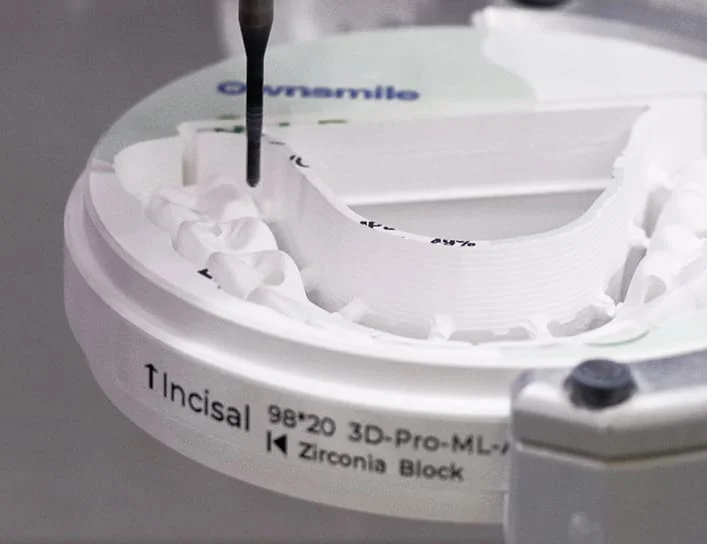

OS-502W Dental Milling Machine

Ownsmile’s latest 5-axis milling solution with seamless integration lets you switch between dry milling and wet milling with ease. Need to handle tough materials or complex cases? Every detail, from the smooth interface to precise performance, helps you stay in control. Your results always stay on point.

-

60,000 rpmSpeed

-

5 axisAxis

-

Dry & WetSupport