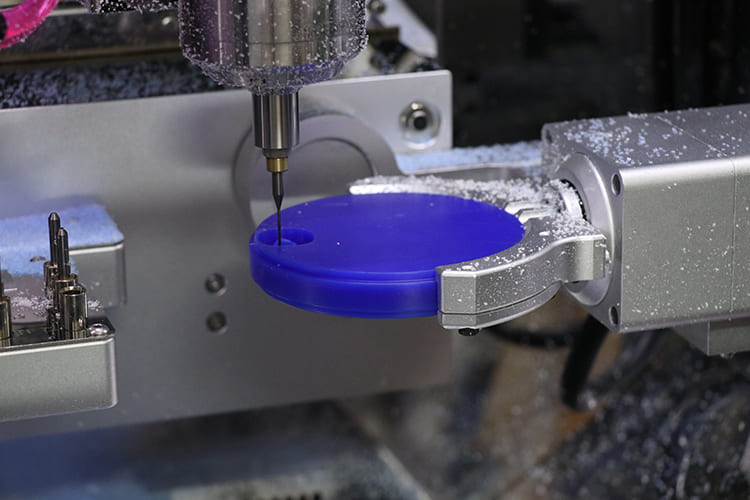

OS-502D Dental Dry Milling Machine

Dry dental milling machine offers advanced precision and efficiency, perfect for modern dental laboratories. Specializing in dry milling, it delivers exceptional results for zirconia, PMMA, and other restorative materials, streamlining workflows and enhancing productivity without wet processing.

-

60,000 rpmSpeed

-

5 axisAxis

-

DrySupport