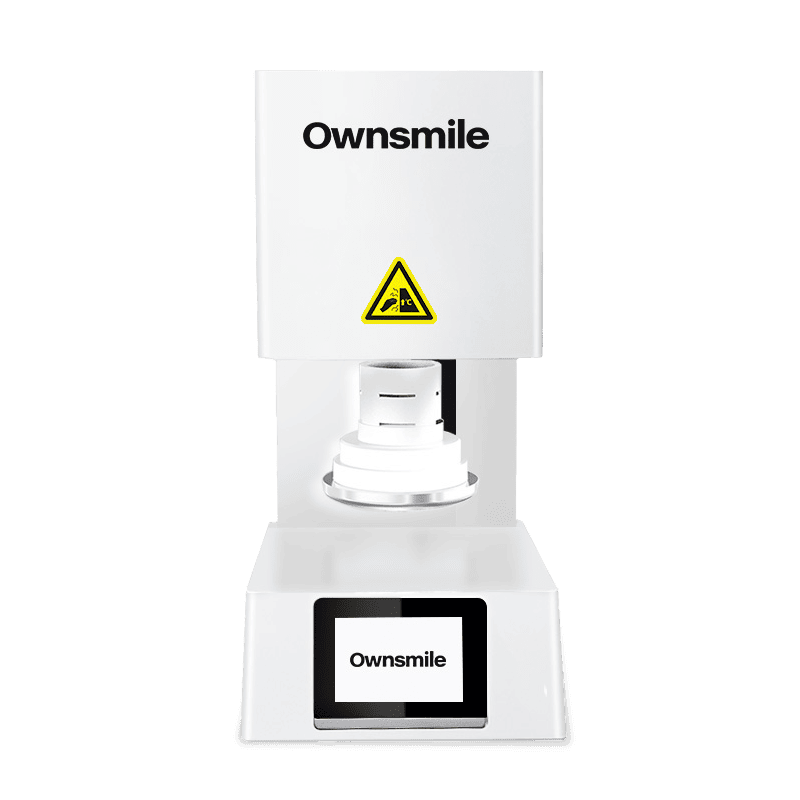

Dental Sintering Furnace

Ownsmile’s dental sintering furnace offers fast sintering, large capacity, and stable high-temperature performance. With intuitive touchscreen control and no preheating required, it streamlines lab workflows while ensuring reliable, high-quality results for zirconia and other dental materials.

-

120 teethCapacity

-

1600C°Temperature

-

30 minSintering Time