-

English

-

Spanish

English

Spanish

You already know the basics of dental milling machines. But when it comes to 4-axis and 5-axis models, how much do you really know about their differences? Which one can handle the restorations you want to produce and match your dental lab’s future plans? Let’s break it down so you can make the right choice with confidence.

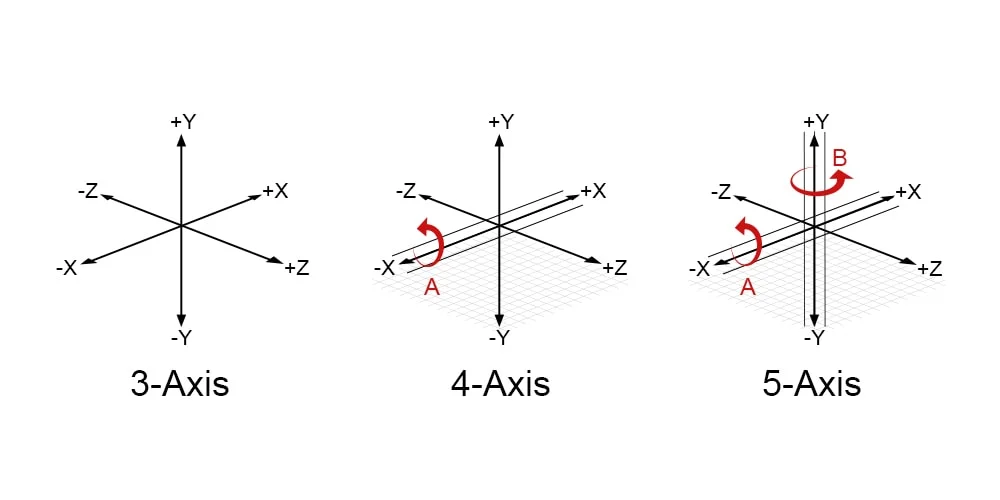

To understand the difference between 4-axis and 5-axis milling machines, it helps to start with the basics. Every dental milling machine moves along three main axes:

With only these three, the tool can cut from the top and sides, but reaching steep angles or deep contours is limited.

A 4-axis machine adds the A-axis, which rotates the material around the X-axis—typically up to about 200°. This wider range allows more cutting angles, ideal for many bridge designs or angled crown preparations, but rotation is in one primary direction. Very steep angles or deep undercuts still require repositioning or cannot be reached.

A 5-axis machine adds both the A-axis and the B-axis. While the A-axis rotates around X (up to a full 360°), the B-axis tilts around Y, typically ±25° to ±65°. Together, they let the tool approach from almost any angle, making it possible to mill complex shapes, deep undercuts, and angled screw channels without stopping to reposition the workpiece.

By adding tilt to the A-axis rotation, the B-axis lets the cutting tool reach the workpiece from nearly any angle. That means fewer repositioning steps, smoother tool paths, and consistent accuracy within 0.02–0.04 mm. Margins seat with precision, and complex geometries like angled screw channels or deep undercuts are milled without manual intervention.

In terms of speed, a 5-axis machine can mill up to 60% faster than a 4-axis model. In tests, producing an inner crown in glass ceramics took about 40 minutes on a 4-axis machine, compared with roughly 25 minutes on a 5-axis system.

With greater accuracy, faster cycles, and the ability to mill from almost any angle, the impact of the B-axis becomes clear when you look at what each system can actually produce in the lab.

Now that we’ve covered the movement capabilities, let’s see how these differences translate into real-world milling applications. The table below outlines common restorative cases, showing which can be handled efficiently by each system and where additional axis movement provides a clear advantage.

Restoration Type / Case | 4-Axis Milling Machine | |

|---|---|---|

Single crowns (Zirconia)/PMMA | ✅ Cost-effective, efficient | ✅ Same capability |

Copings, inlays, standard bridges | ✅ Efficient for high volume | ✅ Same capability |

Temporary restorations, diagnostic wax-ups | ✅ Suitable | ✅ Greater flexibility for complex shapes |

Full-arch implant bridges | ❌ Not supported efficiently | ✅ Essential for angulation and undercuts |

Custom abutments | ❌ Limited capability | ✅ Fully supported |

Angled screw channels | ❌ Not supported | ✅ Fully supported |

Hybrid implant bars | ❌ Not supported | ✅ Fully supported |

Cases with deep undercuts | ❌ Not supported | ✅ Fully supported |

A 4-axis system can complete most daily lab work with ease. When cases involve steep angulation, deep undercuts, or multi-surface milling in a single setup such as custom abutments or full-arch implant bars, a 5-axis system provides the precision and flexibility needed to handle them effectively.

Beyond case capability, other factors such as cost, learning curve, and maintenance requirements can influence the choice.

Feature | 4-Axis Advantages | 4-Axis Considerations | 5-Axis Advantages | 5-Axis Considerations |

|---|---|---|---|---|

Cost | Lower investment | Limited upgrade path | Broad indications | Higher cost |

Learning Curve | Easier for new users | Less versatile | More adaptable | Requires more training |

Maintenance | Fewer moving parts, simpler | May require upgrades sooner | Advanced, future-proof | More complex and costly to maintain |

Throughput | Efficient for simple cases | Slower for complex cases | Handles both simple and complex cases | Slightly slower for basic cases |

Material Utilization | Ideal for standard blocks | Limited for angled abutments | Excellent for complex shapes | May require advanced CAM |

When choosing between a 4-axis and 5-axis dental milling machine, keep these key considerations in mind:

Current Trend:

The dental industry is increasingly moving toward more complex restorations, digital implantology, and highly customized solutions. For labs focused on single-unit work with quick ROI in mind, a 4-axis machine is still a cost-effective choice. However, if your lab or dealership plans to expand, attract high-value clients, or stay ahead with evolving digital workflows, investing in a 5-axis milling machine offers greater flexibility and enhances competitiveness.

In short, here’s what to consider:

Looking to optimize your dental lab workflow? Contact us today. Our experts can help you compare milling machine specifications, evaluate robust spindle performance, and choose the right model for your materials—be it zirconia, wax, PMMA, or metal. If you’re evaluating new equipment, our team can walk you through real case examples and performance data, helping you choose the right system for your workflow.